Technical Services

The company focuses on the research and development and production of seamless steel pipes.

We have established provincial enterprise technology centers, municipal R&D centers, industrial design centers and other scientific research platforms, and our scientific research personnel are fully equipped with professional.

Chemical engineering

Metallurgical equipment and machinery

Material science and engineering

Analysis and testing

Testing and Inspection

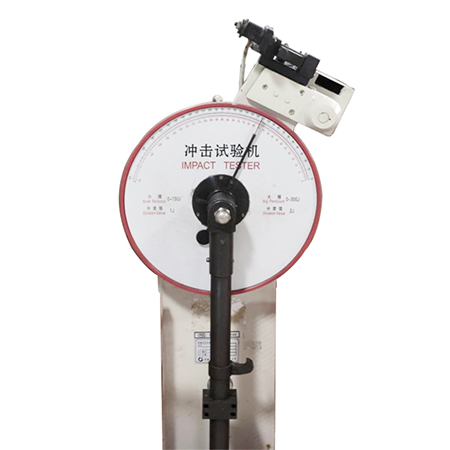

With complete quality inspection equipment and professional quality inspection team

Equipped with various advanced inspection and testing equipment, it lays a solid foundation for the high quality of products.

Carbon / Sulfur Analyzer

Hardness Test

Ultrasonic flaw detector

Tensile testing machine

UT Test

Impact testing machine

Spectral testing machine

Electromagnetic microscope

The company has a complete sales network and after-sales service system.

The products cover more than 30 provinces and cities across the country, with direct warehouses in Shandong, Hebei, Liaoning, Guangdong, Sichuan, Jiangsu, Xinjiang, Inner Mongolia and other places to meet the product needs of different customers, and export to the Middle East, Indonesia, Malaysia, Singapore, Thailand, Iran and other countries and regions. The company always adheres to the concept of focusing on improving product services and meeting customer needs, and provides multi-channel professional after-sales services 24 hours a day to ensure timely and efficient satisfaction of customer needs.

The company attaches great importance to

technological innovation.

Continuously increase investment in scientific and technological research and development, and actively seek cooperation with well-known domestic and foreign universities and research institutes in technology joint development, talent introduction and other aspects while independently developing, promote the deep integration of production, learning and research, and cooperate in more than 10 R&D projects each year. A large number of scientific and technological achievements have been implemented, some of which have reached the domestic leading level, and the core competitiveness is constantly improving.

Main production equipment

Hot delivery and hot charging line for tube billets

High speed hot saw

Continuous pipe mill

Reducer (Sizing machine)

Magnetic flux leakage detector

High pressure water pressure testing machine

Other devices